|

Korean |

|

Korean |

- Company

MessageBusiness & PartnersOrganizationManagementLocation - Services

Vacuum BrazingCasesConsumables - Facilities

Vacuum Heat Treating Furnace(3-Chamber type)Vacuum Heat Treating Furnace(1-Chamber type)Helium Leak DetectorUltrasonic Scanning Equipment - Customer Support

Request for - News

What's NewNote

Cases

Cases

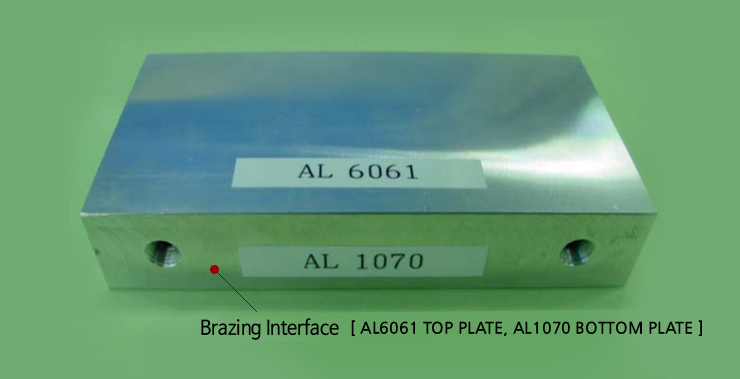

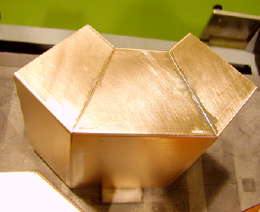

- Al / Al Vacuum Brazing (Fluxless)

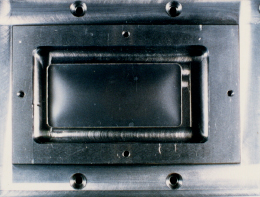

• Aluminum Jacket for water cooling(160L×80W×30t Used filler metal is Al-Si alloy)

• He Leak Test : Less than 1.0×10-10 Pa ㎥/sec

• Tensile Strength : 97 MPa (Parental Metal Ruptured)

• He Leak Test : Less than 1.0×10-10 Pa ㎥/sec

• Tensile Strength : 97 MPa (Parental Metal Ruptured)

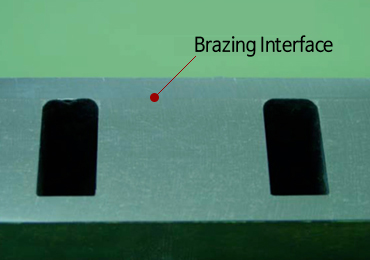

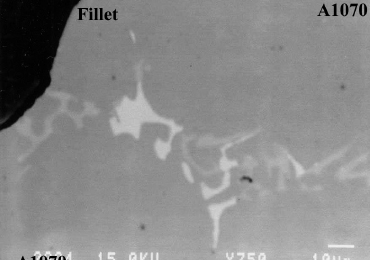

• Cross section

• Brazing Interface

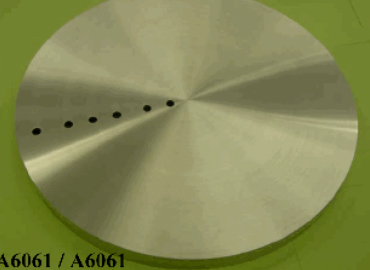

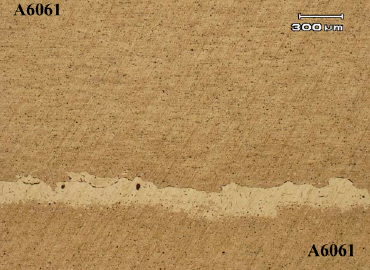

- Al Alloy Vacuum Brazing

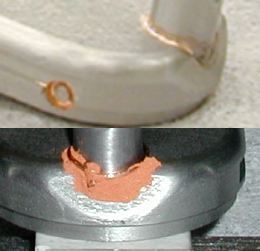

• [ φ400×5t, 20t, 5t / 3-layer brazing ]

Parental Metal Al6061 / Al6061

Parental Metal Al6061 / Al6061

• Cross Section of Macro-etch Test

• Ultrasonic Test Scan Image

- He Leakage : Less than 1.3×10-10 Pa ㎥/sec

- Usage: AL JACKET of Heater, ESC of Semiconductor Equipment, etc

-

Our Company’s Test Data (Shearing Strength)

- Al1100 / AL1100 : approximately 3.5kgf/㎟

- Al6061 / AL6061 : approximately 9.0kgf/㎟ -

UT Scanning Equipment :

Possible to check the surface of joint with ultrasonic upon room-temperature and under water dondision.

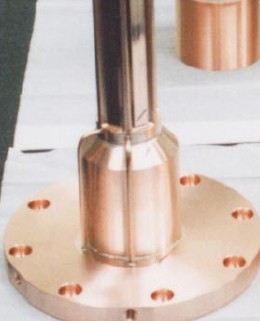

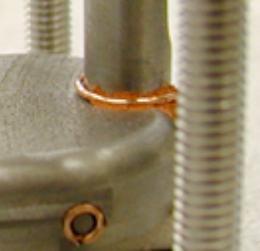

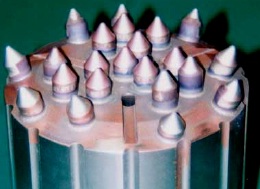

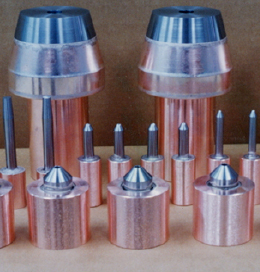

- Vacuum Brazing of Cu Product

-

Applicable Materials

Copper – Oxygen-free Copper(C1020), Phosphorous Deoxidized Copper, Electron Tolerant Oxygen-free Copper, Alumina Spread Copper(Special Operation)

Copper Alloy – Beryllium Copper, Cromium Copper, Phosphor Bronze, Cupro Nickel -

Inapplicable Materials

Copper – Tough-pitch copper

Copper Alloy – Zinc, Lead, Aluminum included copper alloys -

Silver Brazing – V1008 (Melting Point: 780℃)

This is the most-used way because of good junctions. Because Its fluidity is considerably good, it is important to manage clearance when brazing is performed and shape of assembly . (Wire, Thin Film) -

Silver Brazing – V1008-T (Melting Point : 800℃) (Thin Film, Powder), - V1018 (Melting Point : 720℃)(Wire, Thin Film)

It is used for Step Brazing. (It can be used alone) -

Nickel Brazing - V4-BNi-2 (Melting Point : 1000℃) (Powder, Thin Film, Sheet), - V4-BNi-7 (Melting Point : 890℃) (Powder, Thin Film)

It is used for Step Brazing or in special case of high temperature atmosphere. -

Gold Brazing - V-BAu-4 (Melting Point : 950℃)

This can achieve good junctions. However, because of high cost, it is used in special cases such as heat-resisting, corrosion-resisting components or when they are used in high-degree vacuum condition. (Wire, Thin Film) - Palladium Brazing Alternative of Gold Brazing Filler Material

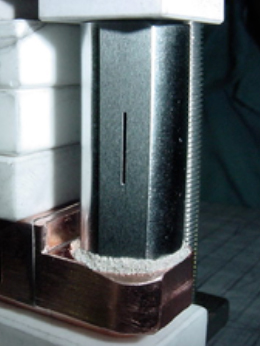

- Vacuum Brazing of Stainless Steel Products

-

Copper Brazing – V54 (Melting Point : 1083℃)

Penetration of Brazing Filler Metal is excellent, so it’s optimal for delicate brazing as well as general brazing.

It has economic cost. (Wire, Thin Film, Powder, Paste) -

Copper·Nickel·Manganese Brazing – V77-24N9 (Melting Point : 960℃)

Penetration of Brazing Filler Metal is good. Brazing temperature is 100℃ lower than Copper. It is possible to perform brazing in solid solution temperature. (Wire, Thin Film) -

Silver Brazing(Contain Ni-Mn) – V1008-2M (Melting Point : 800℃)

Stainless Steel Brazing is available without Ni plating.

It is used when plating is impossible.(Wire, Thin Film) -

Nickel Brazing – V4-BNi-2 (Melting Point : 1000℃)

Corrosive-resisting·Heat-resisting·High-strength Brazing is possible.

Brazing is done in solid solution temperature.

It is the most-used metal in Nickel Brazing. (Wire, Thin Film) -

Nickel Brazing – V4-BNi-5 (Melting Point : 1135℃)

This metal is Corrosive-resisting·Heat-resisting·Boron-free.

It is used to brazing of components with high temperature atmosphere and corrosive environment, and nuclear-related components (Powder, Thin Film, sheet) -

Nickel Brazing – V4-BNi-7 (Melting Point : 890℃)

Brazing in low temperature is possible because of good fluidity.

It is used when thin parental metal can cause fusing effects from alloying or have temperature restrictions. It also can be used in Step Brazing.(Powder, Thin Film)

- Vacuum Brazing of Mo, Ta, Nb Products

-

Copper Brazing – V54 (Melting Point : 1083℃)

Used in brazing of Mo – Mo / Mo – Stainless Steel. (Wire, Thin Film, Powder)

-

Silver Brazing – V1008-T (Melting Point : 800℃)

Used in brazing of Mo-Mo / Mo - Cu / Mo – Stainless Steel.

(Wire, Thin Film, Powder) -

Gold Brazing – V-BAu-4 (Melting Point : 950℃)

Mo, Ta, Nb – Used in brazing of Heterogeneity Metal(Cu, Stainless Steel)

(Wire, Thin Film) -

Nickel Brazing

- V4-BNi-2 (Melting Point : 1000℃)

- V4-BNi-5 (Melting Point : 1135℃)

- V4-BNi-7 (Melting Point : 890℃)

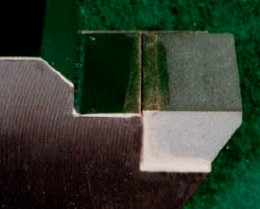

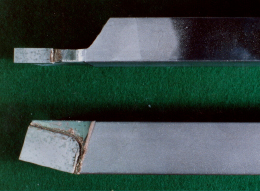

- Vacuum Brazing of Hard Metal(Tunsten)

-

Copper Brazing – V54 (Metling Point : 1083℃)

It has high penetration, good heat resistance and shock resistance.

Reactivity to Hart Metal(Tunsten) is good.

Low cost and economic.

(Wire, Thin Film, Powder) -

Copper-Nickel-Manganese Brazing – V77-24N9 (Melting Point : 960℃)

It has good penetration and reactivity to Hard Metal(Tungsten).

Greater high-temperature strength than Silver brazing filler material.

Highest fusing temperature among Copper-Mn-Ni type brazing filler materials.(Wire, Thin Film, Powder) -

Copper-Nickel-Manganese Brazing

- V77-28N2 (Melting Point : 930℃)(Powder)

- V77-38N9 (Melting Point : 920℃)(Wire, Thin Film) -

Copper-Manganese Brazing – V77-30 (Melting Point : 880℃)

Lowest fusing point among Copper-Mn type brazing filler metal.

Good reactivity to hard metal(Tungsten)

Greater high-temperature strength than silver brazing filler metal. (Wire) -

Silver Brazing – V1008 (Melting Point: 780℃)

Perform brazing by Ni plating to hard metal(Tungsten).

Masking is needed where plating is impossible because Ni plating layer of brazing part is alloyed with brazing filler metal thus not peeled off.

In cases of putting buffer copper plate between hard metal and parental metal when performing brazing, silver brazing filler metal is recommended. (Wire, Thin Film, Powder) -

Silver Brazing(contain Ni-Mn) – V1008-2M (Melting Point : 800℃)

Hard metal / Tungsten Brazing is possible Without plating.

It is brazing filler metal developed by our company, and often used to brazing of Tungsten electrodes. (Wire, Thin Film)